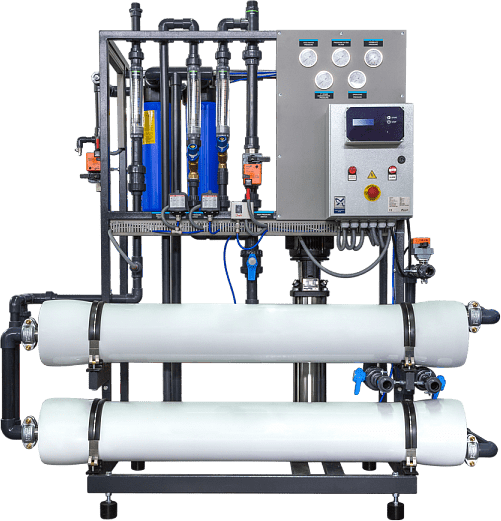

Demineralization of process water

Removing up to 99.8%

of all substances from the water

- Complex removal of all kinds of impurities

- High efficiency up to 99.8%

- Laboratories, plants and factories

- Aquaparks, industry

Usage

Reverse osmosis (R.O.) has a variety of applications. From the desalination of seawater, through the production of ultrapure demineralised water, to thickening of solutions in pharmaceutical and food industry. In water treatment it is mostly used to remove atypical pollutants (nitrates, heavy metals, pesticides), reduce high conductivity (total mineralization) and, mainly, to produce demineralized water.

Demineralized water (low mineral content water, ie low conductivity water) is often required for machine and plant operation. Namely boilers, heat exchangers, cooling circuits, steam generators, or water jet nozzles. Demineralized water is also often used to dilute solutions or to rinse products. Minerals contained in water would cause scale, clogging or contamination in these applications.

Function

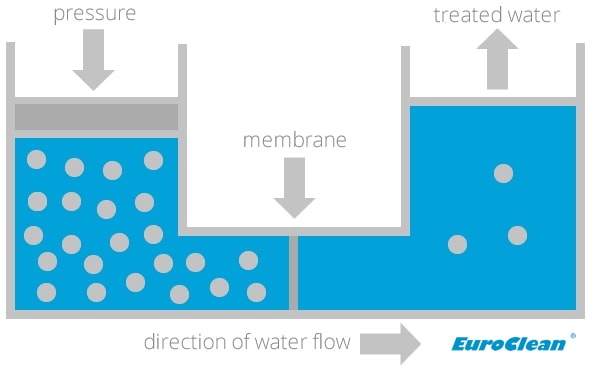

Reverse osmosis is a membrane filtration. The pores of the membranes are so small that even dissolved salt ions, not to mention suspended particles, cant pass through them. Membrane filters are reeled into cylindrical modules. Raw water is pushed through the membrane by high pressure (10 to 50 bar). Pure and demineralized water passing through the membrane is called permeate. It is collected in a storage tank. Part of the water (20-40%) does not pass through and is discharged together with all the impurities (a so-called retentate or concentrate).

Conductivity of the permeate is typically between 10 and 20 μS / cm. In case lower conductivity is needed, a demineralization ion exchanger (AquaBed) is required to be installed after the reverse osmosis. If no such low conductivity values are required, only a portion of the water can be purified by the reverse osmosis, and the rest can pass around via a so-called bypass. In such case, the reduction of minerals concentration is roughly equal to the percentage of water passing through the osmosis.

Installation

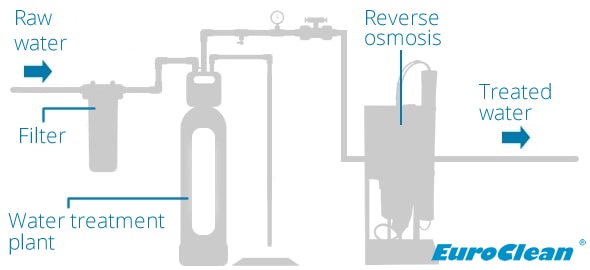

Reverse osmosis membranes are relatively prone to clogging and are damaged by free chlorine. Hence, mechanical prefilter, softening, dechlorination and, if necessary, iron and manganese removal are usually installed prior to reverse osmosis.

Demineralized water flowing from reverse osmosis has insufficient pressure to be directly connected to the pipeline. Therefore, a storage tank and a pump are installed after the device. Larger industrial models usually have an integrated bypass.

efficiency

scope

water