Softening of hard water for industry and factories

Reliably prevents the formation of limescale

- Protects water distribution systems from limescale deposits

- Reduces machine wear and energy consumption

- Protection of exchangers, injection nozzles, reverse osmosis

- Energy, Automotive, Chemical, Electrotechnical

- Food, Engineering and Textile Industry, Laundries, Hospitals

Usage

AquaSoftener is used to soften hard water, reliably prevents the formation of limescale and thus protects water distribution systems from fouling. In plants where water is used for technological purposes, it is often necessary to work completely without calcium and magnesium ions. Hard water causes a number of inconveniences.

There is a build up of limescale deposits in various parts of the system, clogging of pipes and fittings. Even soft water creates deposits if it is heated or thickened. In practice, this is the case particularly for boilers, heat exchangers and reverse osmosis membranes. Last but not least

it can pollute and degrade manufactured products.

Due to softening, device faults occur less frequently and equipment lifetime is prolonged. Thanks to clean surfaces, heat exchange is more efficient, which saves energy. With softened water, detergents can be used in smaller doses.

Function

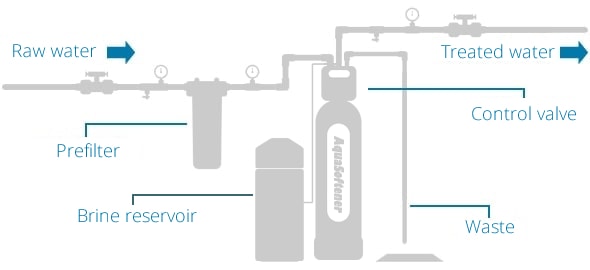

AquaSoftener works on the principle of ion exchange. Calcium and magnesium ions, which cause water hardness, are exchanged for harmless sodium ions.

After filtering a certain amount of water or after a set time has elapsed, regeneration starts.

The operation is fully automatic. During regeneration, the ionex filter bed is washed with salt solution (brine) from a reservoir.

That way is the captured calcium and magnesium rinsed into sewerage and the softener capacity is restored.

Tablet salt in the brine reservoir needs regular resupplementation.

During the regeneration phase is the water supply interrupted. For continuous operation, two softeners can be connected in parallel as a so-called DUPLEX.

Installation

AquaSoftener is connected via a bypass to the main water supply of the facility or of the device. The outlet of rinsing water (which flows out of the filter during the regeneration phase) is introduced into a drain. The final step is to set up the control valve.

The operating costs consist of the tablet salt, water consumed during regeneration, and the small amount of electrical energy needed for the control valve. It is highly dependent on actual hardness of the water. Please contact us to choose the appropriate equipment for you and calculate the cost.

Parameters

| AquaSoftener 500 | AquaSoftener 600 | AquaSoftener 620 | AquaSoftener 650 | AquaSoftener 800 | AquaSoftener 900 | |

| Dimensions in mm (width/height/depth) | 1570x720x460 | 1600x800x460 | 1890x1000x550 | 1980x1100x550 | 2240x1400x740 | 2240x1700x840 |

| Flow (m3/h) | 2,5 | 3,5 | 4,5 | 8 | 10 | 15 |

| Vessel (“) | 10×54 | 13×54 | 16×65 | 18×65 | 24×72 | 30×72 |

| Weight (kg) | 65 | 105 | 155 | 230 | 460 | 690 |

| Input / Output Connections | 1″ | 1″ | 1″ | 2″ | 2″ | 2″ |

| Brine / waste connection | 3/8“ / 1/2“ | 3/8“ / 1/2“ | 3/8“ / 1/2“ | 1/2“ / 1“ | 1/2“ / 1“ | 1/2“ / 6/4“ |

| Brine reservoir volume | 145 l | 145 l | 200 l | 350 l | 350 l | 500 l |

| Average regeneration time (min) | 60 | 60 | 75 | 90 | 90 | 90 |

Power supply: 100-240V | Operating pressure: 1,5 – 6 bar | Operating temperature: 5 – 45 ˚C

For continuous operation, two devices can be connected parallel to each other (DUPLEX).

service life

installation